Product Description

The FWS is been specially designed for critical sort distance welding to make the welding operations very simple for the worker at any construction building site, in pipe trenches, or in workshop.

Application

The LWS is been designed to make the welding operations very simple for the worker at any construction building site, in pipe trenches, or in workshop.

Advance Features

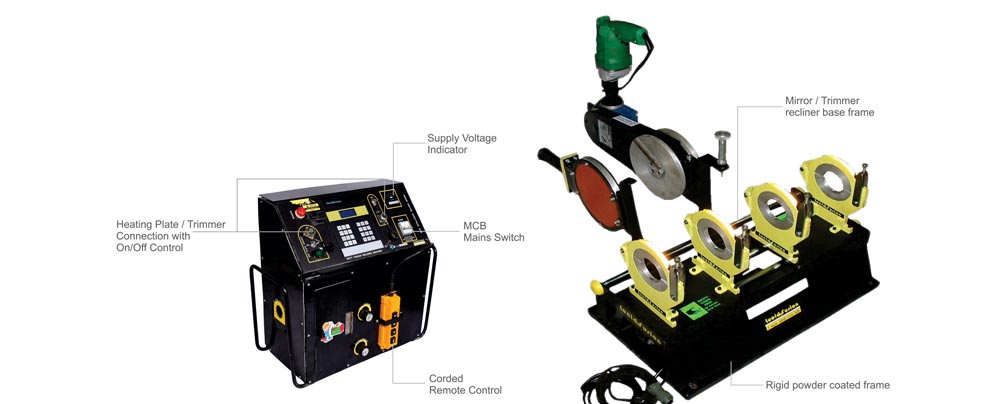

- The FWS has rigid basic frame to support basic main ms clamps specially designed for critical welding operations supported by single hydraulic cylinders and hose pipes with quick couplings.

- The FWS heating plate comes with microprocessor based PID digital temperature controller for butt fusion welding of PE, PP, PPH & PVDF pipes & fittings.

- The FWS has digital pressure indication along with two separate pressure setting valve for drag & jointing which make use of machine very easy with single time setting for same size pipe.

- The FWS has built-in digital timers for soaking & bead-up with loud audible & visual signal.

- The FWS performs intelligently during mirroring process which provides automatic pressure drop from high to low & timer from bead up time to soaking time by buzzer signal with prefix time & pressure data in PLC.

Working Range with Various Model : 230V - 50/60Hz

| Description | ø Suitable Pipe Size | ø Inch | Dimension( ” )

(Machine Body) |

Kg |

|---|---|---|---|---|

| FWS 160 | 32 - 110 mm | 1 - 4” | 26 x 18 x 15 | 32 |

| FWS 250 | 50 - 160 mm | 1½ - 6” | 26 x 18 x 18 | 45 |

Standard Composition

Main Machine Body, Heating Plate with DTC, Trimming Unit,PLC based Electro Hydraulic Unit, Reduce Clamp Inserts.

Optional : Pipe Rollers